1, Test classification

A) First inspection;

B) Quality consistency check.

2, A spring group of groups

The spring shall be inspected according to the batch. Each batch shall consist of the same material specifications, grades, melting furnace numbers and springs made under the same technological conditions.

3, First test

3.1 The inspection of the production of the spring first piece must be carried out according to the test or inspection items specified in the drawings, and the determination of qualified and unqualified shall be made.

3.2 The first piece of spring must be checked and recorded in full. The inspector will inform the technician of the inspection result.

4, Quality conformance test

The scope of application of the 4.1 whole test:

4.1.1 Small batches of springs, such as less than 50 pieces;

4.1.2 Special important missiles, which will endanger personal safety and serious economic losses after damage, such as nuclear power plants, aeroengines, seismographs and other springs.

4.1.3 Can automatically detect items, such as spring load, free height, etc.

4.2 The scope of application of sampling inspection:

4.2.1 Large spring, more than 500 pieces;

4.2.2 High cost, long cycle inspection items, such as fatigue test, creep and relaxation test, etc.

4.2.3 Destructive testing items, such as impact test, metallographic structure, decarburization and hardness test.

4.2.4 Has a certain degree of unqualified inspection items, such as end clearance and verticality, which will not cause much impact.

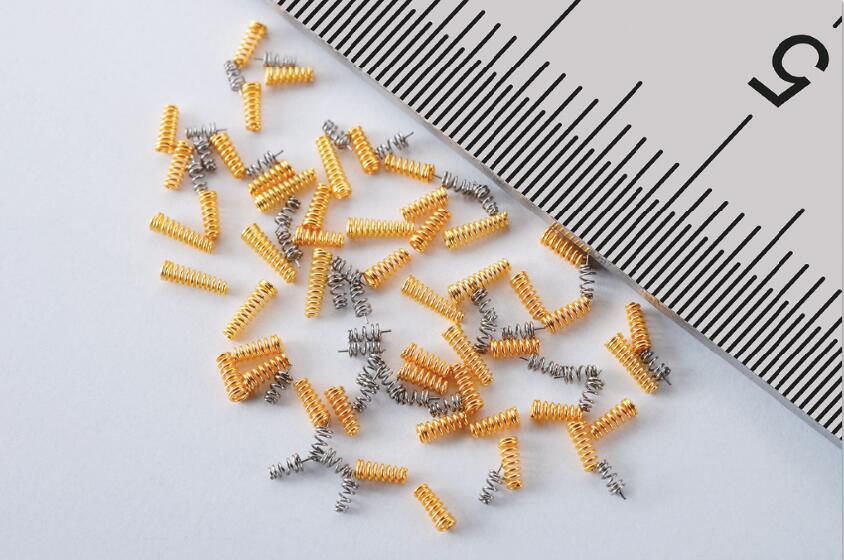

4.2.5 Large quantities of items that cannot be automated inspection, such as the surface quality of springs. There are a wide variety of springs, and their inspection items and requirements can be determined according to the technical standards and specifications of each spring. This paper mainly introduces the inspection and requirements of the cylindrical helical spring products for the reference of other springs.

5. Inspection of the quality of spring appearance

The appearance quality of the spring is visually inspected after oil immersion sandblasting or five times magnifying glass. Ultrasonic testing or magnetic particle testing can also be used for special requirements. The spring appearance quality requirements: the spring ring is not allowed to have obvious distortion and bending. The spring should clear the surface of the surface, salt, lead and oxide. The surface of the spring is not allowed to have cracks, crack, scars, corrosion and so on, but it is allowed to be removed by grinding in the range of material cross section, and the grinding part should be leveled. Slip; the individual scratches, scratches, or dents on the spring surface are not allowed to be greater than half of the diameter tolerance of the material.