Cylindrical spiral spring structure

There are three types of cylindrical spiral spring:

1. Cylindrical spiral compression spring

1) spacing between springs

Let the spring's pitch be p;The diameter of the spring wire is d;In the free state, there should be proper spacing between the circles.In order to make the spring still maintain a certain elasticity after compression, it is also necessary to ensure that there is a certain gap of 1 between each circle under the maximum load.The size of lens 1 is generally recommended to be: in addition 1=0.1d or greater than 0.2mm

2) dead circle

The two ends of the spring are closed with the adjacent ring (no gap), which only supports the spring without deformation.When the number of working rings of the spring is less than or equal to 7, the dead ring at each end of the spring is about 0.75.When n BBB 0 7, the dead ring at each end is about 1 ~ 1.75 turns.

3) end structure

YI type: both end face rings are tightly connected with the adjacent ring and are ground flat on the special grinding machine;

YII type: when the spring wire is heated and wound, both ends of the spring wire are forged flat and tightly connected with the adjacent ring (the end ring can be ground or not ground);

YIII type: both ends of the ring with the adjacent ring and do not wear smooth

In important cases, YI type should be used to ensure that the two supporting ends are perpendicular to the spring axis, so that the spring is not askew when under pressure.When the diameter of the spring wire is less than or equal to 0.5mm, the two supporting end faces of the spring need not be polished.For the spring of d BBB 0 0.5mm, the two supporting end faces shall be ground.The grinding part shall not be less than 3/4 of the circumference.The thickness of the end should not be less than d/8, and the roughness of the end surface should be less than

2.Cylinder coil drawing spring

1) end hook type

For easy connection, fixation and loading, the stretch spring is provided with a hook at both ends.

LI and LII hooks are easy to make and widely used.However, due to the large bending stress generated at the transition point of the hook, it is only suitable for the spring whose diameter of the spring wire is d or less than l0mm.

LVII and LVIII hooks are not combined with spring wires, so there are no disadvantages of the aforementioned transition. Moreover, the hooks can be turned to any direction for easy installation.It is better to use the LVII hook for heavy duty applications, but it is more expensive.

2) stretch spring with prestress

When the cylinder coils are unloaded, the rings should be closed to each other.In addition, in order to save the axial working space, and ensure that the springs in the no-load time each ring compresses each other, usually in the winding process, and at the same time make the spring wire around its own axis to generate torsion.The spring made in this way, each ring has a certain pressure on each other, and a certain prestress is produced in the spring wire, so it is called.This kind of spring must be larger than the initial tension of F0, after each ring began to separate, so that no prestressed stretch spring can save the axial working space.

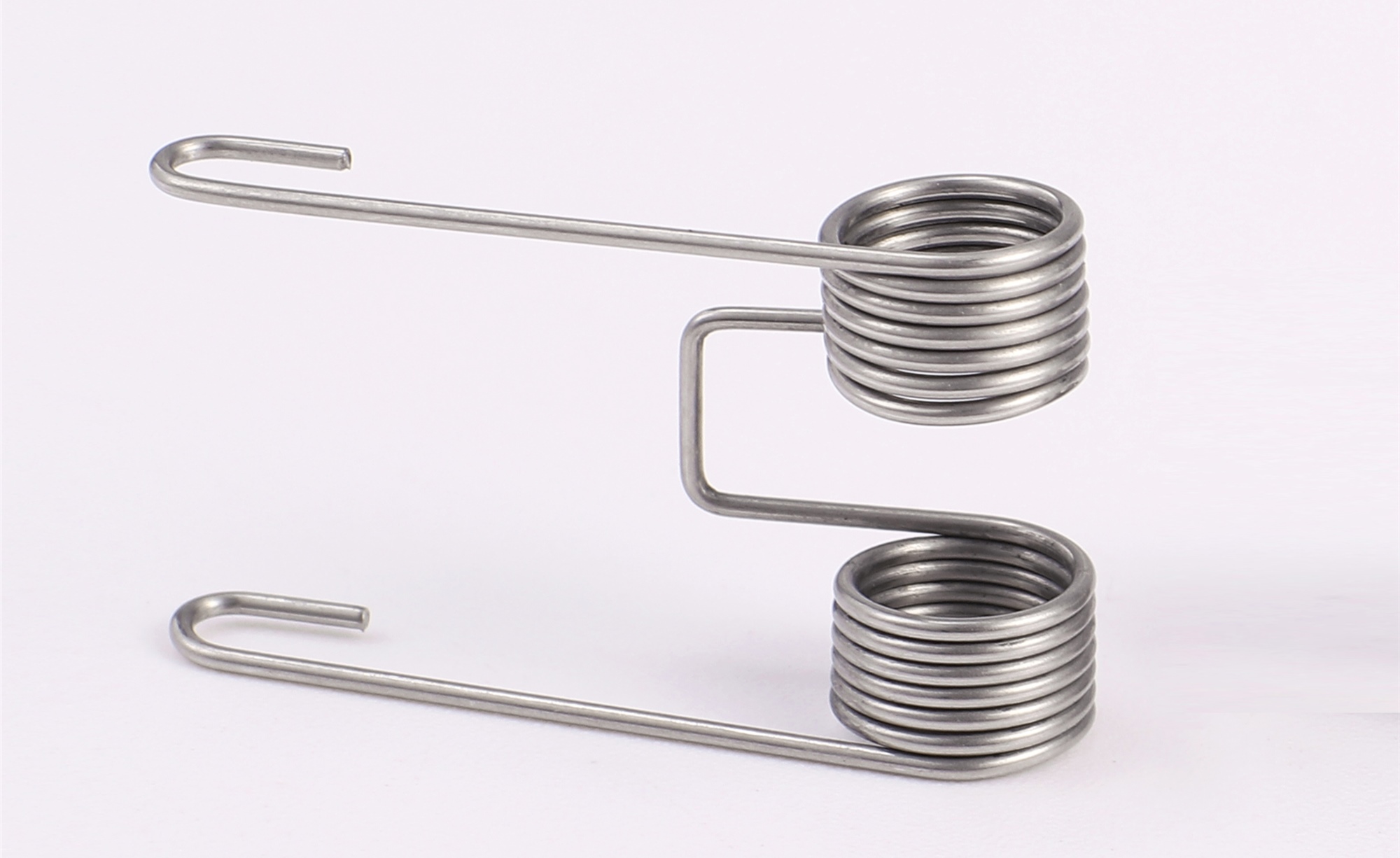

3. Spiral torsion spring

The torsion spring is provided with a lever arm at both ends for easy connection, fixation and loading:

The cylindrical spiral spring is manufactured

The manufacturing process of spiral spring includes: a) rolling;B) the making of the hook or finishing of the face ring;C) heat treatment;D) process test and strong pressure treatment.

Coiling is the winding of spring wire to the mandrel according to the technical requirements.In mass production, it is rolled on universal automatic spring coiler;Single piece and small batch production, in the ordinary lathe or manual winding machine winding.

There are two kinds of rolling: cold roll and hot roll.The cold coil is used for spring wire with diameter d<(8 ~ 10)mm drawn after pre-heat treatment.Stronger springs made of larger diameter spring filaments use hot coils.Hot coil when temperature varies with the thickness of the wire spring in the range of 800 ~ 1000 ℃.The pitch of the spring should be adjusted according to the specific situation, no matter using cold roll or hot roll.

After the above procedure, the spring should be heat treated.The surface of the spring after heat treatment should not have a significant decarburization layer.The spring after the cold coil is tempering only to eliminate the internal stress of the coil.

In addition, the spring must also carry out the process test and the test of precision, impact and fatigue according to the technical conditions of the spring to check whether the spring meets the technical requirements.It should be noted that the durable strength and impact strength of the spring depend to a large extent on the surface condition of spring wire, so the spring wire surface must be smooth and clean without defects such as cracks and scars.Surface decarburization will seriously affect the material's lasting strength and impact resistance.Therefore, the depth of decarburization layer and other surface defects shall be specified in the technical conditions for the acceptance of spring.Important springs shall also be treated with surface protection (e.g. galvanized);A common spring is usually painted with oil or paint.

For important springs, there is also a strong pressure treatment.In order to generate plastic deformation and residual stress in the critical area of the spring wire section, the spring is loaded continuously for 6 ~ 48 hours under the action of ultimate load.Because the residual stress is opposite to the working stress symbol, the maximum working stress of the spring treated with strong pressure is small.If treated by shot peening, increase by 20%.However, springs used in long term vibration, high temperature and corrosive media, as well as springs in general use should not adopt this strengthening process.

Spiral drawing and torsion spring manufacturing, except a few manufacturers in the introduction of foreign CNC CNC spring forming machine last automatic forming process various types of stretch, torsion spring.Most manufacturers still use traditional processing methods to manufacture, now a simple introduction.

1. Coil stretching spring.The process is basically the same as that of the spiral compression spring, except the hook ring processing at the end. The forming method of the stretching spring is as follows:

1) the same method as the screw compression spring is used to conduct de-stress annealing after winding forming, and then the hook ring is processed. In addition to the special shape of the hook ring or the spiral stretching spring with high initial tension is used for lathe winding or manual rolling, most of the springs are rolled by automatic spring winding machine.

2) coil with straight end spring machine.It is a vertical vertical spindle winding machine.After rolling, de-stress annealing and then hook and ring processing.The end structure of coiled stretch spring has many forms and processing methods.Commonly used are: small spring using plier-type special tools or special process equipment for manual processing;The normal spiral stretching spring is processed by the hook or die by manual or automatic operation.The stretching spring of the long arm hook ring is usually the length of material needed for the draw hook to be left out when winding, or the number of rings needed for processing after winding, the two ends are straightened with the straightening tool, and then the hook ring is bent with the special tool.The process specification for de-stressing annealing is described above.After the spring coiling is done, stress relief annealing is carried out first, and then cut off and hook ring processing is carried out. After the hook ring processing is completed, the stress relief annealing should be carried out one or two times in general.In order to prevent two carabiners relative Angle changes, therefore, when the stress relieving to shackle is processed temperature is better than rolling after the low temperature of 20 ~ 30 ° C.Coiled extension springs are generally not shot blasting and tension treatment.

2. Spiral torsion spring.Its craft and spiral compression, tensile spring are basically the same, different embedded instant kang also raise agent ぁ?In the case of small batch production and complicated torsion arm, most of the torsion arm is formed by manual or semi-automatic winding spring method, and then the torsion arm is processed according to the pattern requirements with the jig.In the mass production, it can be rolled on the straight-tail coil spring machine and the special machine for torsion spring. If the torsion arm cannot be completed according to the pattern, it can be processed by the work installation and clamping device.According to the characteristics of the helical torsion spring, the following two points should be noted in the design and manufacture:

1) the twist arm of the end of the spiral torsion spring shall be bent once during manufacturing to avoid machining defects and correct shaping.The second stress relief annealing should be carried out after the torsion arm processing.

2) the current helical torsion springs are mostly close coils, in this way, a compressive force similar to the initial tension of the stretching spring is generated between the spring coils. Friction will be generated during loading and unloading, and hysteresis will occur.It also brings difficulties to the surface treatment process.Therefore, in the design and forming, the spring coil should be slightly left between the gap.In mass production, under conditions, the manufacturer can adopt hydraulic and pneumatic methods to process the spiral drawing, torsion spring expansion, bending and hook.