In order to make it convenient for customers to buy and custom spring, some brief introduction about spring and specification parameters are summarized as follows:

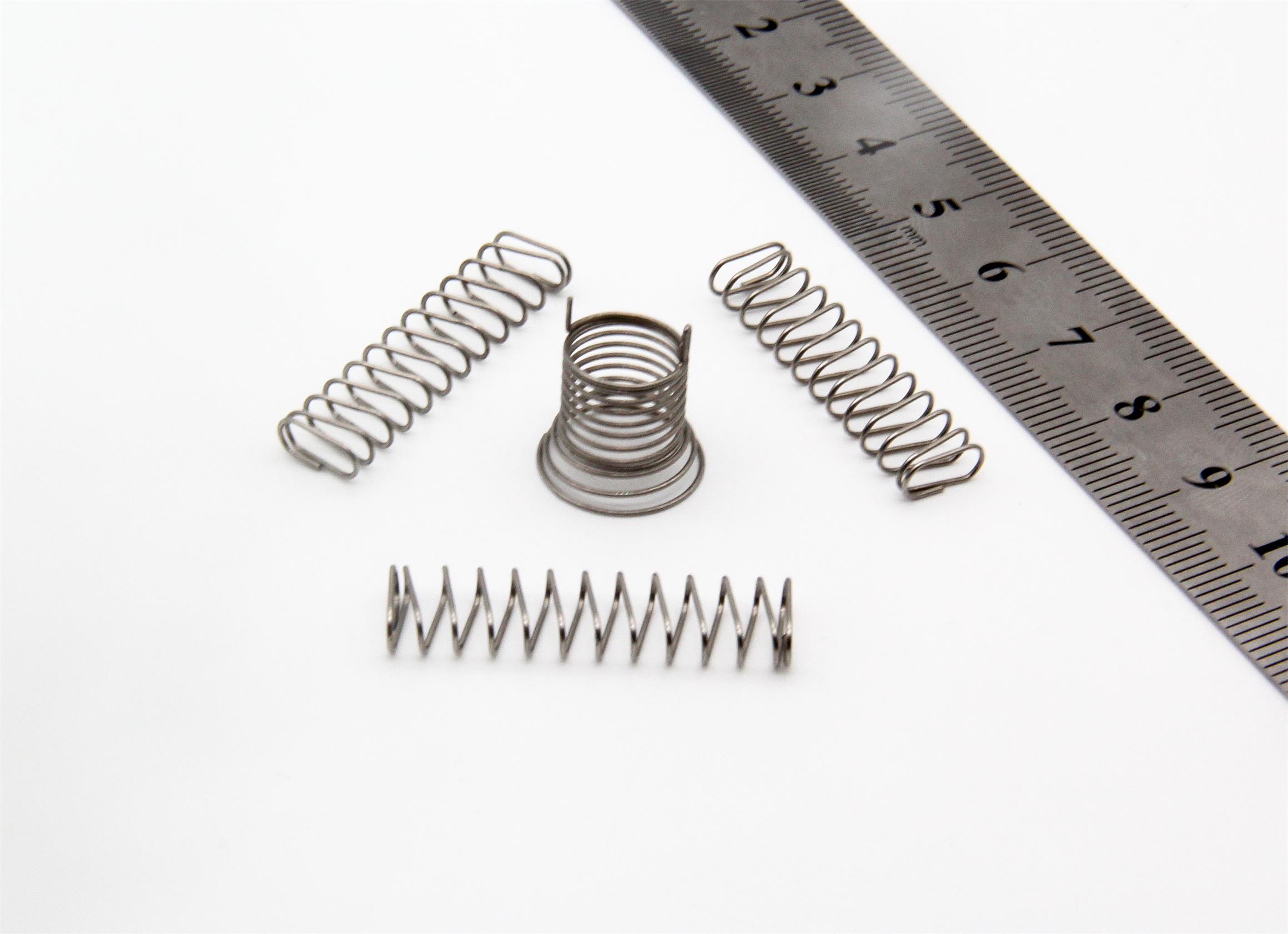

The common spring can be classified as: stretching spiral spring, compression spiral spring and torsion spiral spring.

Among them, stretch and compression springs are mostly produced in quantity, with complicated specifications but suitable for slight modifications. If a small amount of springs is needed and the characteristics of springs are not critical, they can be purchased easily in the market with a higher unit price.

The users of the exclusive mechanism parts are mostly made to professional spring manufacturers.If you can't design it yourself, you can pay the manufacturer to do it.

In recent years, CNC computer control or mechanical spring machine has been adopted in the industry to automate, economize production, and the quality is relatively stable.Based on ISO and international requirements for increasing quality, almost all spring manufacturers can provide report data for testing spring properties.

2. For special occasions, use can be classified as: torsion bar, scroll spring, thin plate spring, disc spring, wavy spring, spring washer, ring spring, ring spring and other special spring.

Specifications and dimensions of spiral spring:

3-1. Diameter: the main characteristic of spiral spring is the diameter.

3-2. Outside diameter: it is convenient to measure the outside diameter of the spiral spring and easy to identify the size.

3-3. Winding number: total winding number, effective winding number, closed end winding number;The helix spring can bear the opposite force, partly depending on the number of turns.

3-4. Pitch (lead) : the varying distance between the head and tail of a coil spring line on the axis.

This value is usually taken care of only when a compressed spring is made and the spring user does not have to specify how far away it is.

Free length: the length of the spring when no force is applied on both ends of the spring.In general, free length has nothing to do with spring function, and unless the closed ends are ground and machined, a relatively loose tolerance range is allowed, or strict requirements on size are not made.

3-6. Action length: when the spiral spring is compressed or stretched to a fixed length, there should be reaction force value to make the matched item work.

Free Angle: the value of the Angle of the torsion spring when the two legs are not rotated by force applied.Generally speaking, the Angle formed between the two torsion spring feet is not exactly the same in the free state, and is not required or allowed to have a looser tolerance range unless otherwise required for special occasions.

3-8. Angle of action: when the two ends of the torsion spring are applied different directions to twist to a fixed Angle, there should be reaction load and torque value, so that the matched item can be used.

3-9. Spring constant: the axial force generated in each unit length when the spiral spring is stretched and compressed to bear the deformation of external forces.Or the torsion spring of the radial force bearing rotation, at each unit Angle of reaction.

In the graph corresponding to length x and force y, the intersection is almost a straight line.

3-10. Length units: mm (mm) is commonly used, and inch (inch) is commonly used in Europe and America.

3-11. Load unit: the standard term for force is N (Newton), or Kgf (kg force) (g force), as is customary.