The selection of spring material shall be determined according to the properties of the spring bearing load, stress state, stress size, working temperature, environmental medium, service life, requirements for conducting and magnetic conductivity, technical performance, material source and price, etc.

When determining the shape and size of the material section, the series sizes specified in the national standards and ministerial standards should be selected first, and non-standard series of materials should be avoided as far as possible.

Medium and small-sized springs, especially spiral-tension springs, should be preferentially used steel wire, cold-drawn steel wire such as strengthened steel wire, lead bath and oil hardened tempered steel wire, which has higher strength and good surface quality, higher fatigue performance than ordinary tempered tempered steel wire, simple processing, good technology and stable quality.

The carbon spring steel wire and the piano steel wire produced large residual stress after cold drawing. After processing the spring, there was large residual stress, and the size changed greatly after tempering, so it was difficult to control the dimensional accuracy.Oil hardened tempered steel wire is modulated and strengthened after steel wire is drawn to the specified size. Basically, there is no residual stress. After forming spring is tempered at low temperature, the size change is very small, and the heat resistance is better than that of cold-drawn reinforced steel wire.

For large and medium sized springs, cold drawn materials or polished steel after cold drawn shall be used for those with higher load accuracy and stress.Hot rolled steel can be used for spring with low loading accuracy and stress.

The steel plate spring is usually made of 55Si2Mn, 60Si2MnA, 55SiMnVB, 55SiMnMoV, 60CrMn, 60CrMnB and other grades of flat steel.

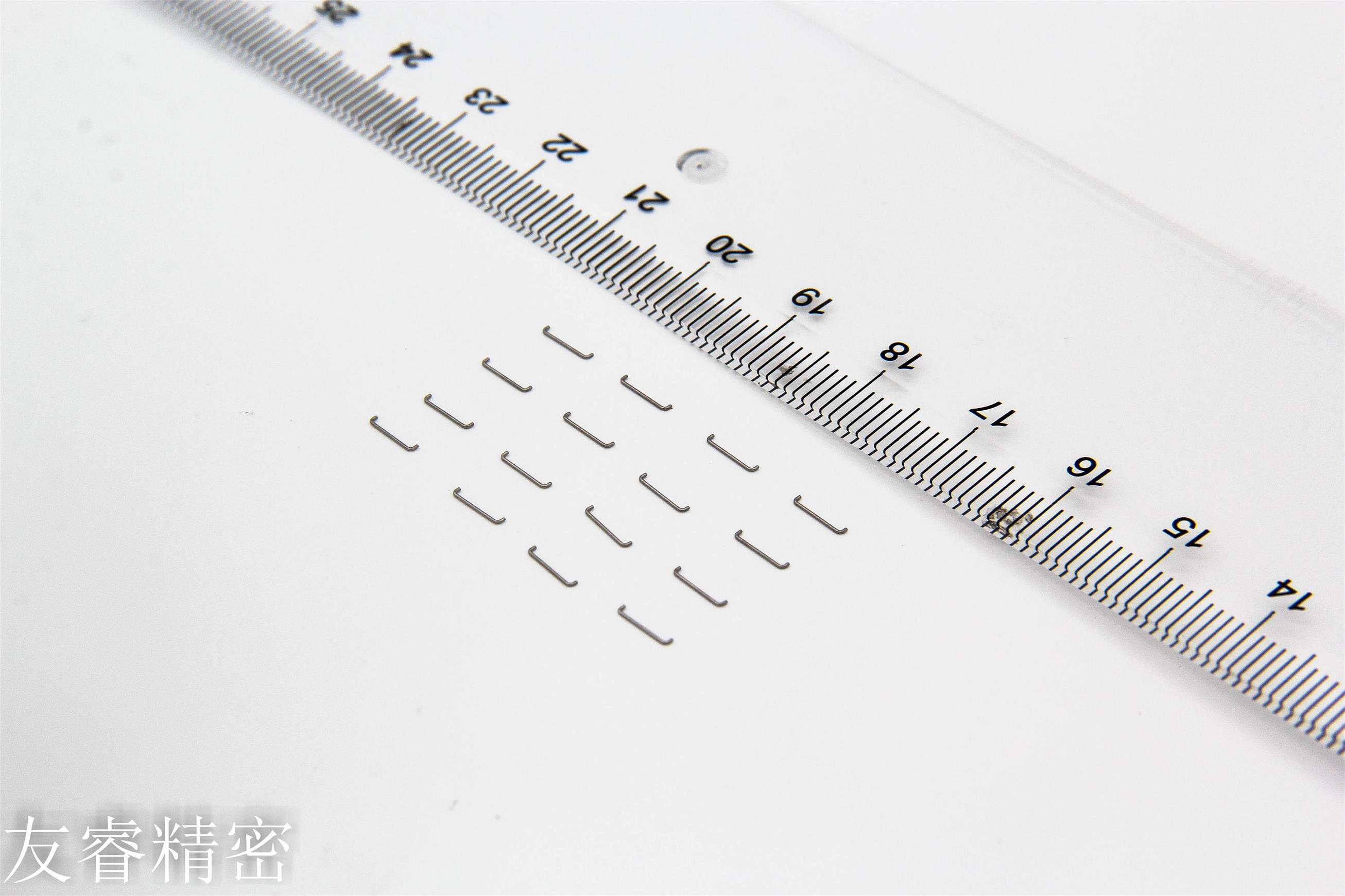

For the material section of spiral spring, circular section should be preferred.Square and rectangular materials have strong bearing capacity, good impact resistance, and can make the spring miniature, but the sources of materials are few.And the price is higher, except special need, do not choose this kind of material as far as possible commonly.In recent years, the circular steel wire is developed to replace the trapezoidal steel wire.

Spring material working under high temperature requires good thermal stability, resistance to relaxation or creep, oxidation resistance and corrosion resistance to certain medium.

As the working temperature of the spring increases, the elastic modulus of the spring material decreases, resulting in lower stiffness and less load bearing capacity.Therefore, the spring working at high temperature must understand the change rate (value) of the elastic modulus and calculate the impact of the decline of the spring's load capacity on the performance.According to the regulations of the GB1239, ordinary helical spring working temperature above 60 ℃, a modification should be made for the shear modulus, its formula is: Gt = G in the KtG type - room temperature modulus of elasticity;Gt -- shear modulus at operating temperature t;Kt -- temperature correction coefficient is selected according to table 2 -- 98.

The spring material used at low temperature shall have good low temperature toughness.Carbon spring steel wire, piano steel wire and 1Cr18Ni9 austenitic stainless steel spring steel wire, copper alloy and nickel alloy have good low temperature toughness and strength.

At low temperature, the brittleness of the material is very sensitive to surface defects.

At low temperatures, the environmental medium is much less corrosive to the material than in a greenhouse, and cadmium plating and galvanizing can easily cause cold brittleness.

At low temperature, the elastic modulus and expansion coefficient of the material do not change much.

The spring made of spring steel, hardness (that is, strength) should be selected according to the load bearing property and stress.However, the degree of hardness is strongly related to the plane strain fracture toughness.

As the hardness increases, the plane strain fracture toughness (KIC) value decreases significantly.That is to say, when determining the spring's hardness value, the spring's hardness value should be lower on the premise of satisfying the spring's characteristics.

When selecting spring material, pay attention to the hardenability of steel.Whether or not the cross section of the spring material is quenched and the degree of quenching is very important to the spring mass.

Electrical springs that use the spring itself as a conductor or work in conditions of varying humidity, such as water (including seawater) and water vapor, are generally made of copper and gold.

Springs operating under acid contact and other corrosive media generally use corrosion resistant materials such as stainless steel or nickel alloy.The spring used under general environmental conditions is made of ordinary spring steel, which is then coated with rust or plated (galvanized, cadmium plated and copper plated) on the surface to prevent corrosion.

In order to satisfy the requirement that the precision of the spring used in the weighing apparatus and instruments is not affected by the temperature change, the constant elastic alloy with minimum elastic modulus and expansion coefficient is generally selected.

In the requirements of light, insulation, anti - collision, corrosion and other special use of spring, can choose reinforced plastics.At present, the more suitable plastic spring is epoxy resin, phenolic resin as the matrix, glass fiber reinforced thermosetting reinforced plastic GFRP.Also may choose the vibration - proof rubber manufacture each kind of rubber spring.