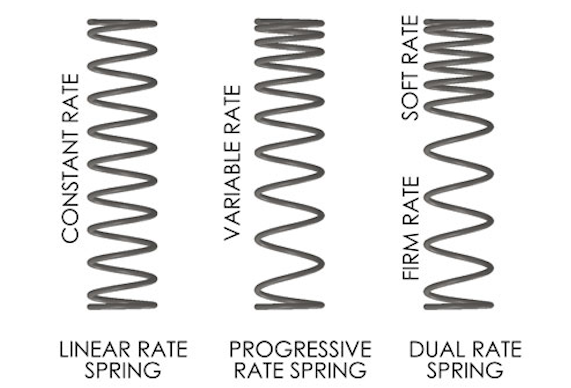

We can look at the relationship between the force applied to a spring and its resulting displacement. Again, there are three classes of springs: linear (or constant rate) springs, variable rate springs, and constant force springs.

Linear springs

Linear springs obey Hooke’s Law (F=k*x), which means that the force needed to extend or compress such a spring by distance x is proportional to the distance, as long as the force doesn’t exceed the elastic limit of the spring. Torsion springs obey an analogous version of Hooke’s Law (F=k*θ, where θ is an angle). In both cases, k is the spring rate, and it stays constant, no matter the spring’s deflection. This is why linear springs are also known as constant rate springs.

Variable rate springs

On the other hand, a variable rate spring doesn’t have the same spring rate throughout its axial length. You can have a progressive change in the spring rate, or a more abrupt change—see the diagram below.

• A familiar variable rate spring is the cone-shaped compression spring, most commonly found in battery boxes. The fully compressed height can be as low as one wire diameter. Variable rate springs also have the additional benefit of being laterally stable and less prone to buckling.

Constant force springs

Self-explanatory by its name, a constant force spring requires nearly the same force, no matter how long the extension. Constant force springs are also called clock springs. This type of spring is usually a coiled ribbon of spring steel used in counterbalancing applications, such as height adjustment for monitors, and—you guessed it—clocks.